Research And Development

Bry-Air has always been at the forefront of technology and innovation through extensive R&D in moisture control, air treatment and optimisation of energy efficiency. Bry-Air’s efforts to introduce the best in class, energy-smart technologies result in continuous R&D in designs, layouts, machinery and production methods which are integrated into the everyday work pattern. Bry-Air’s position today is a result of its research-driven development strategy.

Bry-Air’s R&D facilities are recognized by the Department of Science and Technology and are the best in the environment control industry, worldwide, in the corporate sector

Pahwa Group with Bry-Air and Desiccant Rotors International (DRI), at its helm is the fastest-growing adsorption technology group in the world.

The R&D at Bry-Air focuses on continuously providing the customer with Energy Smart Green Products through:

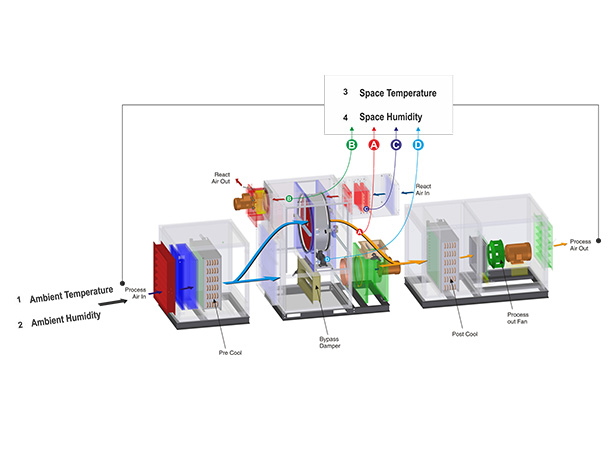

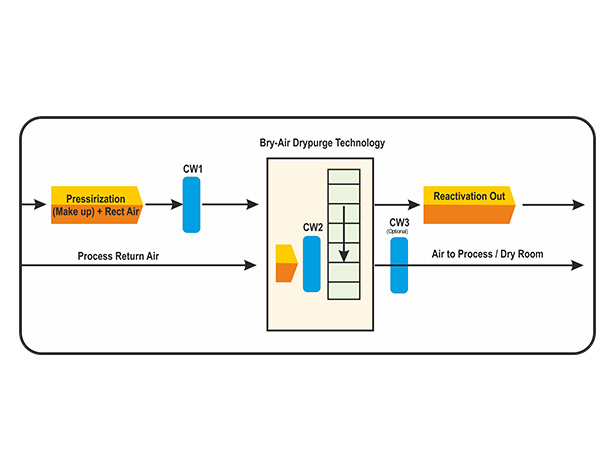

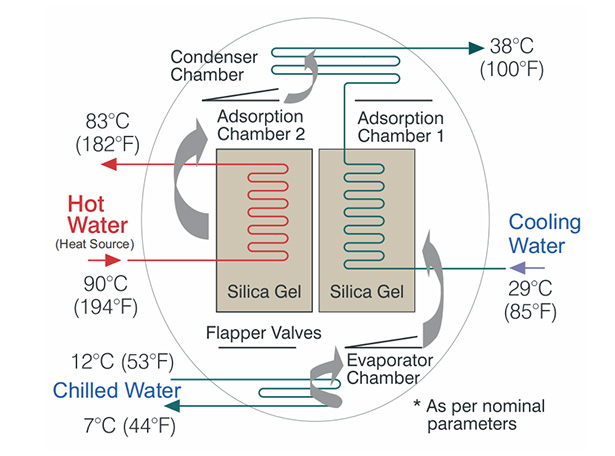

![]() R&D on new technologies and materials as well as on controls and sensors

R&D on new technologies and materials as well as on controls and sensors

![]() Design standardization through simulation, optimization and globalization

Design standardization through simulation, optimization and globalization

![]() Innovative product and process development

Innovative product and process development

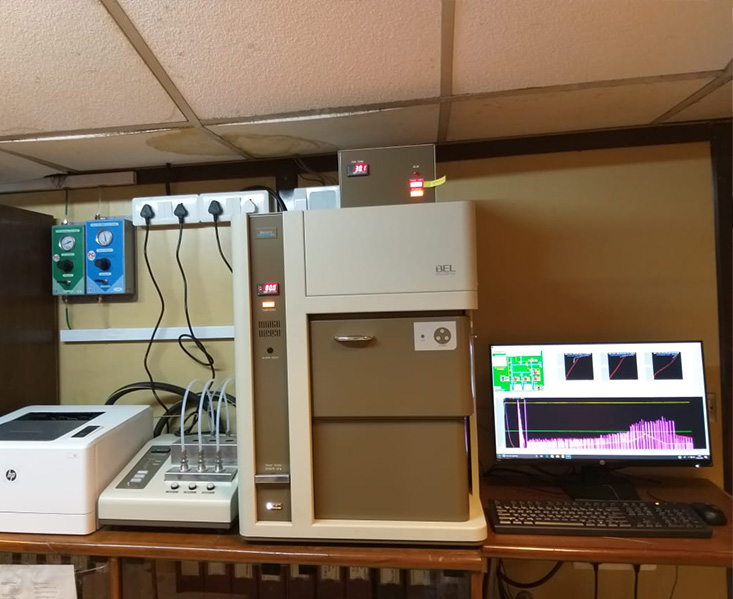

![]() Testing and certification of products

Testing and certification of products