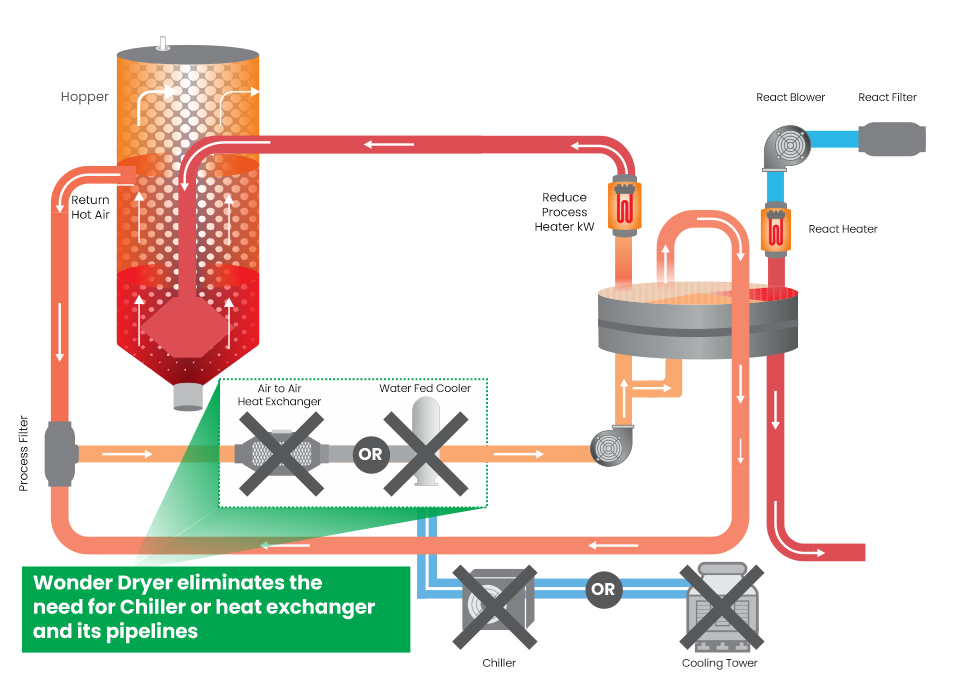

Wonder dryer from Bry-Air, also known as Waterless Plastic Dryer is an energy-efficient revolutionary Plastic Dryer which is waterless in the truest sense.

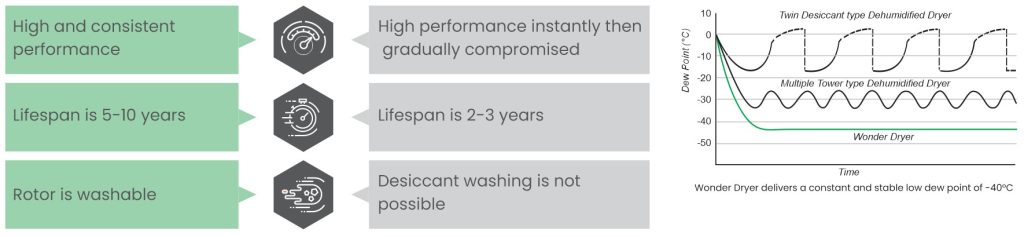

It is launched specifically to cater to the drying needs of next-generation plastic materials, this dryer is able to deliver < (-) 40 °C dew point even at 80°C return air to desiccant rotor inlet.

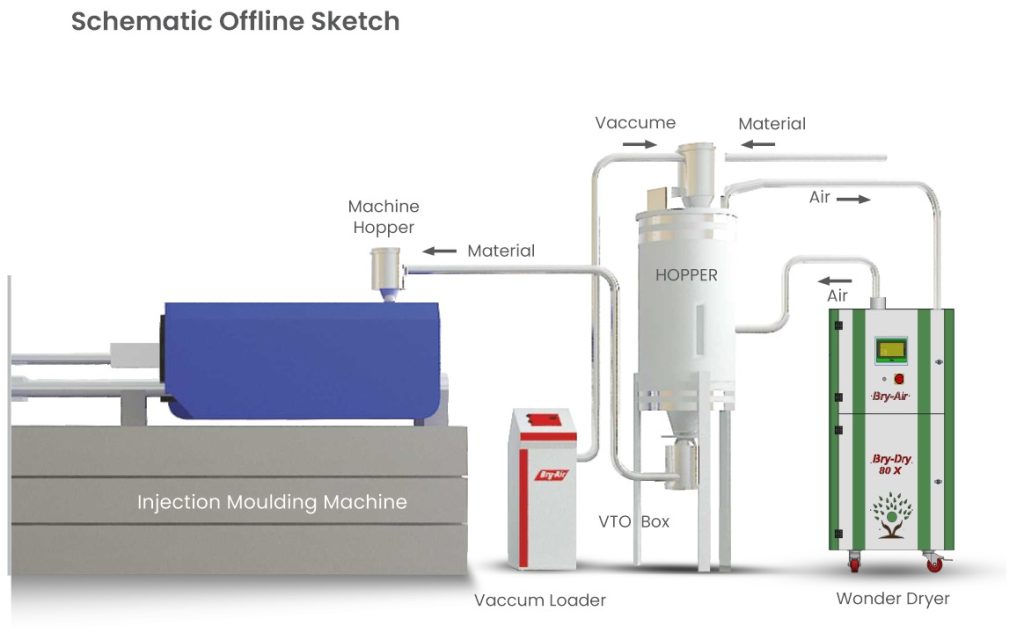

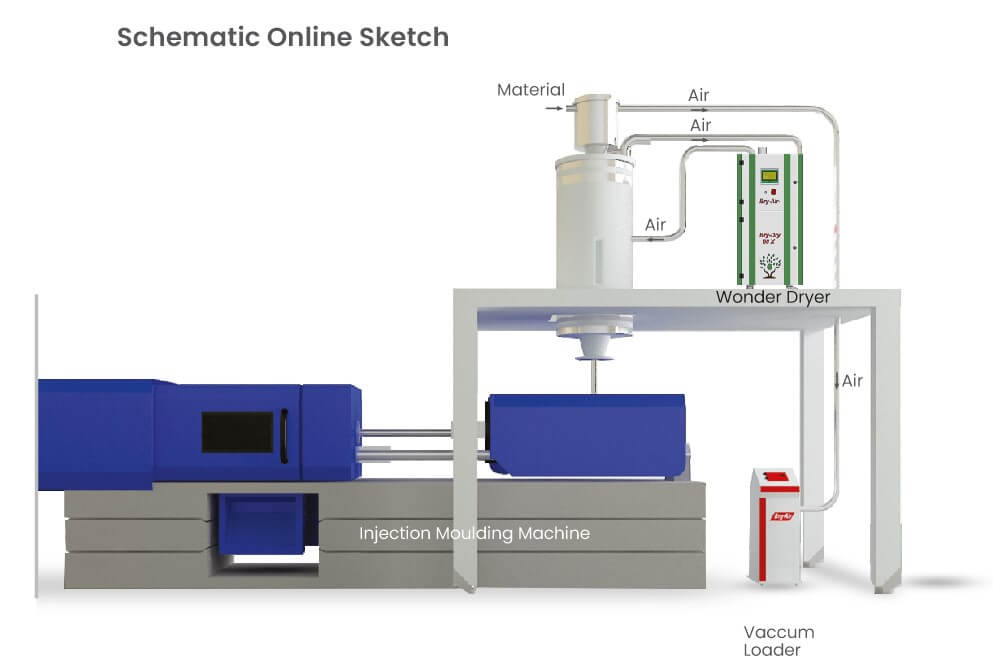

Bry-Air Wonder Dryers are developed to meet the new age plastics drying needs. It is a green product which delivers up to a 40 % reduction in running costs. In addition to the above, the dryer provides great mobility and portability and eliminates the hassle of cooling connection water hoses and dripping/leakage of condensed water. It is ideal for processors that require energy-efficient solutions with convenience and portability.

The Wonder Dryer comes embedded with honeycomb rotor technology with special geometry and chemistry. It helps reduce the operating expense and other capital expense costs leading to significant savings which is difficult to derive from other dryers currently available in the market. The return on investment vis-a-vis a standard dryer is faster and hence, the Bry-Air Wonder Dryer is slated to be the next breakthrough in Plastic Drying.

Installation Options

Honeycomb Vs. Twin Towers

Bry-Air Knows Drying Best and with over 60 years of experience in desiccant drying, it has yet again come up with a revolutionary drying solution for Plastic Processors. Bry-Air Dryers come with credibility and leadership in desiccant dehumidification and adsorption technologies across the globe.

All Wonder Dryer-series floor-mount cabinet-style dryers come standard with:

- High efficiency and reliability

- A totally self contained unit

- CNC fabricated unit(s) with powder coated finish

- Process air high temperature paper filter

- Waterless plastic dryer, can achieve ≤ (-)40°C at rotor inlet air condition ≤ 80°C

- With pre cool, can achieve ≤ (-)60°C at rotor inlet air condition ≤ 35°C

- Rotor incorporates robust internal structure for industries quality and durability

- Rotor is non-flammble with organics < 2%

- Hard face coating on rotor edge ensures long life good sealing for media and seals

- Process and reactivation air flow sectors are insulated

- Unique PTFE coated silicone flat seal

- World wide proved Siemens make electrical switchgears for safety and reliability

Ease of Operation

- BrySmartTM (Microprocessor based controller) to supervise the operation, fault management along with display messaging of RS 232 serial data interface to retrieve stored data in the data log

- Remote fault warning output to activate an audible alarm or warning lamp at a remote location

- Intelligent re-start following a power failure

- Programmable security code to prevent unauthorized mishandling

- Intelligent power circuit switching to minimize voltage drops in unit supply system

- Alpha-numeric fault display

- Real time clock/calendar

- Battery backup of settings

Ease of Installation

- Castor wheel mounted cabinet for easy movement

- Versatile, easy to package and handle

- Small footprints; low volume/weight per CMH

Options

Digital dew point meter

|

MODEL

|

Process

Air Inflow CMH

|

Hose Connection in Inch

|

Outlet Temp. Range In (°C)

|

Process Blower (KW

|

React Blower (KW)

|

Bed Drive Motor (KW)

|

Process Heater

KW

|

Process Heater

KW

|

P OUT Dew Point °C

|

Dimensions in (mm)

|

Full Load (amp)

|

Shipping

Weight

(KG)

|

|

For 120°C

|

For 180°C

|

Connect

|

Running

|

W

|

D

|

H

|

|

*BRY DRY-30

|

30

|

2

|

80-180

|

0.18

|

0.18

|

0.006

|

0.75

|

1.25

|

1.5

|

0.6

|

-40

|

560

|

660

|

1500

|

16

|

175

|

|

*BRY DRY-60

|

60

|

2

|

80-180

|

0.40

|

0.18

|

0.006

|

1.25

|

2.5

|

1.5

|

1.1

|

-40

|

560

|

660

|

1500

|

22

|

185

|

|

BRY DRY-120

|

120

|

3

|

80-180

|

0.90

|

0.40

|

0.006

|

2.25

|

5.0

|

2.75

|

2.3

|

-40

|

830

|

950

|

1745

|

14

|

340

|

|

BRY DRY-170

|

170

|

4

|

80-180

|

1.75

|

0.40

|

0.006

|

3.25

|

7.0

|

3.75

|

3.2

|

-40

|

830

|

950

|

1745

|

20

|

350

|

|

BRY DRY-225

|

225

|

4

|

80-180

|

2.20

|

0.40

|

0.006

|

4.25

|

9.0

|

5.0

|

4.3

|

-40

|

830

|

950

|

1745

|

26

|

360

|

|

BRY DRY-300

|

300

|

4

|

80-180

|

5.50

|

0.75

|

0.025

|

5.75

|

12.0

|

6.75

|

5.7

|

-40

|

830

|

950

|

1745

|

40

|

420

|

|

BRY DRY-400

|

400

|

6

|

80-180

|

5.50

|

0.90

|

0.025

|

7.50

|

16.0

|

9.0

|

7.6

|

-40

|

1090

|

1320

|

1920

|

48

|

570

|

|

BRY DRY-500

|

500

|

6

|

80-180

|

9.00

|

1.75

|

0.025

|

9.0

|

20.3

|

11.25

|

9.5

|

-40

|

1090

|

1320

|

1920

|

66

|

600

|

|

BRY DRY-750

|

750

|

6

|

80-180

|

9.00

|

2.20

|

0.025

|

13.5

|

30.0

|

18.0

|

14.3

|

-40

|

1090

|

1320

|

1920

|

89

|

635

|

|

BRY DRY-1000

|

1000

|

6

|

80-180

|

5.60

|

0.75

|

0.025

|

20.0

|

40.0

|

22.5

|

19.1

|

-40

|

1645

|

1945

|

2180

|

95

|

885

|

|

BRY DRY-1250

|

1250

|

10

|

80-180

|

5.60

|

1.12

|

0.025

|

25.0

|

50.0

|

27.5

|

23.9

|

-40

|

1645

|

1945

|

2180

|

129

|

895

|

|

BRY DRY-1750

|

1750

|

10

|

80-180

|

7.50

|

1.12

|

0.025

|

33.0

|

69.4

|

38.5

|

33.4

|

-40

|

1645

|

1945

|

2180

|

164

|

910

|

|

BRY DRY-2500

|

2500

|

10

|

80-180

|

9.30

|

1.50

|

0.040

|

46.2

|

99.0

|

59.4

|

47.7

|

-40

|

–

|

–

|

–

|

–

|

–

|

|

BRY DRY-3500

|

3500

|

10

|

80-180

|

15.00

|

2.20

|

0.040

|

66.3

|

138.9

|

79.2

|

66.8

|

-40

|

–

|

–

|

–

|

–

|

–

|

|

* Indicates unit available in 230/1/50Hz only

|

All data subject to change without notice

|

|

Resin Type

|

Drying Temp.°C

|

Time Hours

|

BRY DRY – 30

|

BRY DRY –

60

|

BRY

DRY –

120

|

BRY

DRY –

170

|

BRY

DRY –

225

|

BRY

DRY –

300

|

BRY

DRY –

400

|

BRY

DRY –

500

|

BRY

DRY –

750

|

BRY

DRY –

1000

|

BRY

DRY –

1250

|

BRY

DRY –

1750

|

BRY

DRY –

2500

|

BRY

DRY –

3500

|

|

ABS

|

80-85

|

2-3

|

17

|

34

|

68

|

97

|

128

|

171

|

229

|

286

|

429

|

571

|

714

|

1000

|

1430

|

2000

|

|

PA6/6

|

70-90

|

5-6

|

12

|

24

|

48

|

68

|

90

|

120

|

160

|

200

|

300

|

400

|

500

|

700

|

1000

|

1400

|

|

PC

|

120

|

3-4

|

16

|

33

|

67

|

94

|

125

|

167

|

222

|

278

|

417

|

556

|

694

|

972

|

1390

|

1950

|

|

PET

|

160-180

|

4-5

|

13

|

27

|

53

|

76

|

100

|

133

|

178

|

222

|

333

|

444

|

556

|

778

|

1111

|

1556

|

|

PMMA

|

80

|

3-4

|

13

|

26

|

52

|

74

|

98

|

130

|

173

|

217

|

326

|

434

|

543

|

760

|

1086

|

1520

|

|

PPO

|

90-110

|

2-3

|

15

|

30

|

60

|

85

|

113

|

150

|

200

|

250

|

375

|

500

|

625

|

875

|

1250

|

1750

|

|

SAN

|

80

|

2-3

|

16

|

32

|

64

|

91

|

121

|

162

|

216

|

270

|

405

|

540

|

675

|

945

|

1351

|

1890

|

|

PBT

|

120-135

|

3-4

|

15

|

30

|

60

|

85

|

113

|

150

|

200

|

250

|

375

|

500

|

625

|

875

|

1250

|

1750

|

|

PPL/PSU

|

90-100

|

3-4

|

16

|

32

|

64

|

91

|

121

|

162

|

216

|

270

|

405

|

540

|

675

|

945

|

1351

|

1890

|

|

Note: As mentioned above, drying rates are based on -40°C dewpoint. For improved drying rate at reduced dewpoint, please consult BAA factory.

|