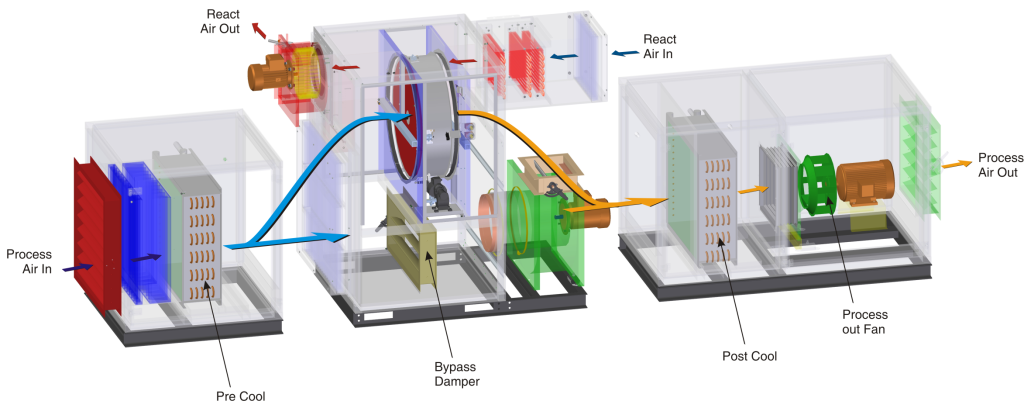

Designed aesthetically, Bry-Air’s Industrial Dehumidifiers, FLi series, can be packaged with:

- Pre filter

- After Filter

- Pre cooling (fresh air cooling)

- Post cooling

- Bypass arrangement for complete air handling and environment control needs

Engineered to highest consistency, reliability, and ecology standards, the FLi rotary type, industrial desiccant dehumidifier removes moisture from air on a continuous basis.

The FLi Dehumidifier incorporates the highly effective EcoDry metal silicate desiccant synthesized rotor to meet the industry needs, having small footprint coupled with high moisture removal capability.

EcoDry at The Heart Of It

The EcoDry Dehumidifying Rotors are the result of many man-years of in-depth study and research on countless permutations and combinations of substrates, desiccants and chemical processes. Every parameter has been considered to maximize performance, durability and applicability.

Advantages with EcoDry Inside

- Adsorbent, non-toxic, non-flammable, fully water washable

- In-situ synthesized metal silicate desiccant on an inert inorganic fibre substrate

- Active desiccant 80% of the media weight, so as to ensure high performance and minimal heat carry-over

- Rotor is non-flammable. The net organics in the honeycomb media less than 2%

- Special edge hardened media surface to ensure a smooth surface and long life of both, media and the seal contacting it

- Rotor perimeter flange extend media and seal life

- Rotor incorporates robust internal structure with perimeter flange for industrial quality, durability and easy serviceability

Standard Features

High Efficiency and Reliability

- Enhanced moisture removal capabilities

- Fitted with a high-performance EcoDry rotor that ensures low volume/weight per CMH and additional moisture removal

- Minimized air leakage (equipped with EU-4 grade filters and unique PTFE bonded bulb seal design)

Superior Design

- Self-contained unit

- Robust stainless steel frame with double skin construction, internal GI sheet and pre-coated external skid for longer life

- CNC fabricated with industrial grade coating

- Flexibility of stainless steel internal skin available for specialised applications in the food, pharmaceutical and other critical industry applications

- Multiple choice of reactivation heat source – electrical, steam, thermic fluid, direct/indirect fired gas

- In bolt process bypass for custom designing of process air flow or process temperature control

- Insulation of process and reactivation airflow sectors

Ease of Installation

- Small footprint

- Versatile, easy to package and handle

Ease of Operation and Maintenance

- Rotor is water washable

- Quick serviceability & maintenance free operation

- Auto/Manual selector switch

- Volume control dampers for both (P&R) air flow

- Easy tool-free access to all components

Customization Options Available

- Humidity control by humidistat on/off

- Airtight, easy to package and integrate additional pre/after cooler modules, higher grade filter

- Stainless steel construction

- Reactivation cool down safety device

- Microprocessor based state of the art BrySmart controller provides a digital display of the status of faults, warning, temperature and RH

- Ethernet & Remote connectivity

- Bacnet

- Modbus

|

|

- Real-time monitoring/control of dehumidifier for both stand-alone and customised systems from remote locations

- Quick troubleshooting by expert technical staff without being at the site, thus reducing the break-down time and related costs

- Helps optimise energy utilisation based on data logging and corresponding solutions

- IP based controls result in low running costs

- Assists customer in authorisation on data logging and set parameter changes

- Availability of trend analysis on a real-time basis

|

The FLi Series Bry-Air dehumidifiers operate on a simplified principle of desiccant dehumidification, utilizing the highly effective EcoDry rotor for moisture removal.

Air Intake and Filtration: Moist air is drawn into the unit and passes through a pre-filter to remove particulates.

Moisture Adsorption: The filtered air then moves through the EcoDry rotor where the desiccant material adsorbs moisture.

Pre and Post Cooling: Depending on customer’s requirement, air can be:

- Pre-cooled before dehumidification

- Post-cooled later

- Both Pre and post-cooled

to achieve desired temperature levels.

Bypass Arrangement: A bypass damper allows for control of air handling based on the specific environment control needs.

Reactivation: A separate air stream, heated by various heat sources, passes through the desiccant rotor in the opposite direction to regenerate the desiccant.

Moisture Exhaust: The humid air from the reactivation process is then discharged outside.

The FLi dehumidifiers, with their robust and efficient design, provide consistent and reliable moisture control, tailored for industrial applications.

FLi series Specification… Process Airflow – 2,500 CMH to 25,000 CMH

|

Dimensional Data (Inches)

|

|

MODEL

|

ROTOR

|

PURGE

|

PROCESS

AIR FLOW

CMH

|

PROCESS

ESP

(pa.)

|

PROCESS

MOTOR

KW

|

REACT

AIR FLOW

CMH

|

REACT

ESP

(pa.)

|

REACT MOTOR

KW

|

REACT HEATER

KW

|

POWER* REQD.

|

Approx Weight

(kg.)

|

Dimension

(L x D x H)

|

|

DEPTH

|

|

Fli 2500

|

200

|

NO

|

2500

|

300

|

1.5

|

833

|

250

|

0.746

|

26

|

415/3/50

|

500

|

2600 x 1220 x 1770

|

|

Fli 3000

|

200

|

NO

|

3000

|

300

|

1.5

|

1000

|

250

|

0.746

|

33

|

415/3/50

|

500

|

2600 x 1220 x 1770

|

|

Fli 4200

|

200

|

NO

|

4200

|

300

|

2.2

|

1400

|

250

|

1.1

|

46

|

415/3/50

|

550

|

2600 x 1220 x 1770

|

|

Fli 5000

|

200

|

NO

|

5000

|

300

|

3.7

|

1667

|

250

|

1.1

|

53

|

415/3/50

|

550

|

2600 x 1220 x 1770

|

|

Fli 6200

|

200

|

NO

|

6200

|

300

|

2.2

|

2067

|

250

|

1.5

|

64

|

415/3/50

|

950

|

2600 x 1400 x 1950

|

|

Fli 7300

|

200

|

NO

|

7300

|

300

|

3.7

|

2433

|

250

|

1.5

|

76

|

415/3/50

|

950

|

2600 x 1400 x 1950

|

|

Fli 8000

|

200

|

NO

|

8000

|

300

|

3.7

|

2667

|

250

|

1.5

|

85

|

415/3/50

|

1025

|

2730 x 1600 x 2150

|

|

Fli 9000

|

200

|

NO

|

9000

|

300

|

3.7

|

3000

|

250

|

2.2

|

96

|

415/3/50

|

1025

|

2730 x 1600 x 2150

|

|

Fli 10500

|

200

|

NO

|

10500

|

300

|

3.7

|

3500

|

250

|

2.24

|

114

|

415/3/50

|

1025

|

2730 x 1600 x 2150

|

|

Fli 15000

|

200

|

NO

|

15000

|

350

|

7.5

|

5000

|

250

|

3.7

|

178.5

|

415/3/50

|

2000

|

3850 x 2050 x 2350

|

|

Fli 15000

|

400

|

NO

|

15000

|

350

|

9.3

|

5000

|

250

|

5.5

|

178.5

|

415/3/50

|

2150

|

3850 x 2050 x 2350

|

|

Fli 15000

|

200

|

YES

|

15000

|

350

|

7.5

|

5000

|

250

|

5.5

|

168

|

415/3/50

|

2000

|

3850 x 2050 x 2350

|

|

Fli 15000

|

400

|

YES

|

15000

|

350

|

9.3

|

5000

|

250

|

7.5

|

168

|

415/3/50

|

2150

|

3850 x 2050 x 2350

|

|

Fli 25000

|

200

|

NO

|

25000

|

350

|

11

|

8333

|

250

|

7.5

|

294

|

415/3/50

|

2650

|

4350 x 2400 x 3000

|

|

Fli 25000

|

400

|

NO

|

25000

|

350

|

15

|

8333

|

250

|

7.5

|

294

|

415/3/50

|

2800

|

4350 x 2400 x 3000

|

|

Fli 25000

|

200

|

YES

|

25000

|

350

|

11

|

8333

|

250

|

7.5

|

273

|

415/3/50

|

2650

|

4350 x 2400 x 3000

|

|

Fli 25000

|

400

|

YES

|

25000

|

350

|

15

|

8333

|

250

|

15

|

273

|

415/3/50

|

2800

|

4350 x 2400 x 3000

|

Note:

• Other voltage available are 200/220/240/415/440/460 VAC, 3Ph, 50/60 Hz

• Fli 15000 and Fli 25000 come with 200mm and 400mm rotor options and with or without purge

• Because of our policy of continuous product improvements, specifications are subject to change without notice