Bry-Air’s Control Room Industrial Air Purifier is a custom-designed solution for control rooms to shield electronic equipment from the threat of electronic corrosion and abrupt failures. It is caused by corrosive gases and particulate contaminants that seep into the control rooms.

Corrosive gases such as NOx, SOx, Cl2, NH3, O3, HF, H2S, VOCs and particulate contaminants such as PM10, PM5 are either generated in-house (within the plant) or emerging from the nearby industrial areas, landfill sites and open drains and seep into critical control rooms.

Bry-Air Control Room Air Purifier houses a revolutionary Honeycomb Chemical Filter which is the heart of the system. This next-generation revolutionary new medium is a building block of our new custom-designed solution for data centres.

Damage Caused by Harmful Gases and Contaminants

- Deterioration of circuit lines and connectors

- Mechanical deterioration of printed circuit boards (PCB)

- Increased contact resistance

- Leakage in current and short circuits

- Leakage of EMC – shielding

- Creep corrosion

Bry-Air Control Room Air Purifier is manufactured to the highest quality, reliability and ecological standards to control damage. It is a self-contained, standalone, movable unit that purifies and re-circulates the air in an enclosed space.

Features of DRISORB™ Honeycomb Chemical Filter

- High bulk density

- High structural strength (SS-filter cassette) and adsorption capacity

- Suitable impregnation to neutralise various gases

- UL-certified

- Easy to handle

- Longer mean time between replacements (MTBR)

- Tested as per ASHRAE 145.2 and ISO 1155-2 standards

Advantages

Easy to operate

- Suitable for continuous operation

- Manual switch for operating the system

- Easy to handle due to low weight

- Optimum space utilization

Easy to install

- Versatile, easy to package and handle

- Small footprint, low volume/weight per CMH

Easy to maintain

- Quick and easy to service

- Easy honeycomb media replacement

- Easy, tool-free access to all major components

- Quick serviceability and maintenance-free operation

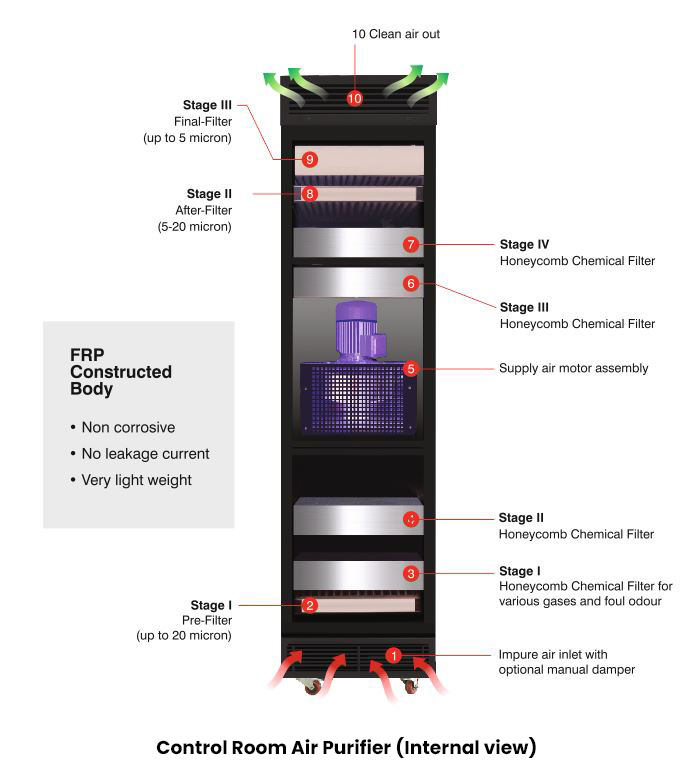

Bry-Air Data Control Room Air Purifier works in three stages. At stage I, the contaminated laden air enters through the bottom grill and air is pre-filtered from larger particulates. At stage II, it is made to pass through the multiple beds of DRISORBTM chemical filters. The corrosive gases are captured and neutralised in the filter by an adsorption and chemisorption process. At stage III, air is filtered again to remove sub-micron particulates. Eventually, the clean air is released from the top.

Features of Filter Used

- Pre filter, 2″ deep, 20% efficiency, ASHRAE standard filtration

- Post filter, 2″ deep, 20% efficiency, ASHRAE standard filtration

- Post Fine filter, 4″ deep, efficiency : 99% down to 5 micron ASHRAE standard

Bry-Air purification systems remove both corrosive gases and contaminants from the air and supply air free of contaminant gases to the controlled environment. It also reduces energy consumption because of very low-pressure drop over traditional media and aids to meet ANSI/ISA-71.04-2013 standard in critical control rooms.

|

Model

|

Air Flow

|

ESP

|

Motor

|

Power Required

|

Total Weight

|

|

CMH

|

CFM

|

Pa

|

KW

|

VAC/Φ/Hz

|

Kg

|

|

CAP-500-2

|

850

|

500

|

250

|

0.75

|

415/3/50

|

165

|

|

CAP-500-4

|

850

|

500

|

250

|

1.12

|

415/3/50

|

180

|

|

CAP-1000-2

|

1700

|

1000

|

250

|

1.12

|

415/3/50

|

205

|

|

CAP-1000-4

|

1700

|

1000

|

250

|

1.5

|

415/3/50

|

225

|

|

CAP-1500-2

|

2550

|

1500

|

250

|

2.24

|

415/3/50

|

260

|

|

CAP-1500-4

|

2550

|

1500

|

250

|

3.73

|

415/3/50

|

290

|

|

CAP-2000-2

|

3400

|

2000

|

250

|

3.73

|

415/3/50

|

320

|

|

CAP-2000-4

|

3400

|

2000

|

250

|

3.73

|

415/3/50

|

360

|