When the minutest layer of corrosion builds up on the circuit surfaces of electronic systems at data centres, server rooms, control rooms, it aggravates electrical resistance and decrements equipment performance. Thus, installation of corrosion monitoring device is recommended to ensure early detection of corrosion potential, which can improve electrical systems performance.

Atmospheric Corrosivity Monitor provides qualitative and quantitative details of the overall corrosion potential of an environment (room) through copper and silver sensors.

It also measures and monitors the room temperature, relative humidity and the differential pressure (optional). It is based on Quartz Crystal Microbalance (QCM) technology. It measures the weight gain as a consequence of corrosion built up on the copper and silver plated sensors surfaces. The weight gain is translated to film thickness and the corresponding corrosivity classification level. The measurements are extrapolated in 24 hours for 30 days to know the severity level as per ISA standards.

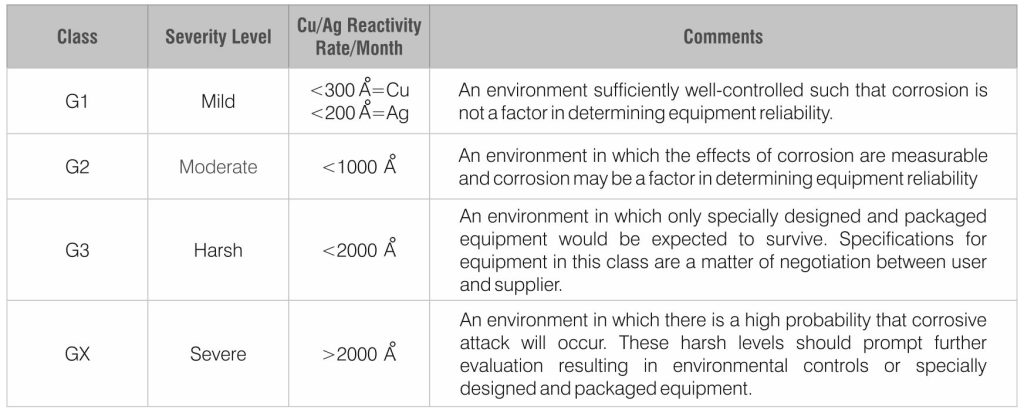

Bry-Air Atmospheric Corrosivity Monitor diagnoses the corrosion of an environment according to the ANSI/ISA-71.04-2013 outlining the severity of corrosion from G1 (mild) to Gx (severe) environment. Reactivity monitoring can be used to characterise the destructive potential of an environment. Measurement of the thickness of corrosion film provides an excellent indication of the type(s) and level(s) of all corrosive gases present in the local environment.

Why do we need to measure atmospheric corrosion and reactivity rate?

Often it is seen that the environmental threats posed by fire, power, temperature, humidity and airborne particulates have long been recognized and successfully addressed in the server-room environment, but the corrosive potential of the air has been largely ignored. Even extremely low levels of contaminant gases at the ppb level corrode and damage the sensitive electronic cards in your servers. Excessive corrosion often leads to electronics warranty non-compliance, circuit board failure, ghost signalling, and even complete failure of electronics components.

Environments with higher atmospheric and air contamination require greater attention to air quality management. The interactive result of temperature variations and humidity with the gaseous contaminants has the potential to increase the threat of air corrosion, providing greater reasons for close monitoring of the immediate environment of IT infrastructure. All companies dealing with sensitive IT infrastructure such as data centres, server rooms, and control rooms, as a core part of their operations, need to implement a comprehensive checking and monitoring mechanism for the corrosion potential of the gases inside their facility. The ISA standards define or characterise environments in terms of their overall corrosion potential.

Environmental Classification as per ISA-71.04.2013 (in Å)

Based on the proven Quartz Crystal Microbalance (QCM) technology in which frequency output changes due to changes in weight. The stable digital output is not prone to drifts or errors and can be easily processed. The unit utilises copper and silver-coated quartz crystal microbalances and monitors the weight gain as a consequence of corrosion built up on the metal surfaces. The weight gain is translated to film thickness and the corresponding corrosion classification level.

Advantage

- Understanding corrosion pattern and measuring corrosion rate

- Verifying effectiveness of corrosion control methods

Some Additional Features

- Remote monitoring and controlling

- RoHS compliant

- Calibration available

- Battery operated

- Internal data storage

- Alphanumeric message/alarm flash

- No external software required to operate and download data

- Easy to install and operate

ACM model BCM232 monitors the overall reactivity levels of gaseous airborne contaminants present. Reactivity Monitoring provides an exact and dependable way to evaluate the corrosivity potential of indoor air and also the effectiveness of installed filter systems.

|

Model

|

BCM 232

|

|

Material

|

Aluminium with powder coated

|

|

Accuracy

|

Within +/- 0.5-1% of full span

|

|

Power Output – Signal Analog

|

4-20 mA

|

|

Power Input – Operation Voltage

|

18-36V DC

|

|

Sensor life

|

4000 Å each

|

|

Dimension (LxWxH) in cm3

|

26 x 12 x 9 cm3

|

|

Weight

|

< 1000 gm

|

|

Logger Time, Interval of Sampling

|

Starts from 2 min to 120 min

|

Installation Environment

- Dry and controlled environment

- Free from excess vibrations

- Can be wall mounted

Function of Atmospheric Corrosivity Monitor

Atmospheric Corrosivity Monitor helps in monitoring the following:

Model Material Accuracy Power Output – signal Analog Power input – Operation Voltage Sensor life Dimension (LxWxH) in cm Weight Logger time, Interval of Sampling BCM 232 Aluminium with powder coated Within +/- 0.5-1% of full span 4-20 mA 18-36V DC 4000 Å each 3 26 x 12 x 9 cm < 1000 gm Starts from 2 min to 120 min.

Communication Capabilities

- 4-20 mA connection – process control system

- Local PC through LAN (wi-fi or ethernet)

- Remote PC through Internet router (wi-fi or ethernet)

- Easy access to data and graphs

- Building Management System connectivity through RS485

- DCS connectivity

- Enable email alerts for alarm threshold

- USB port for easy connection to any PC or laptop

Atmospheric Corrosivity Monitor enables measurement of the corrosion potential of an enclosed environment with ease and accuracy on a real-time basis. It is used across various industries that include:

- Petrochemical refineries

- Paper and pulp industry

- Wastewater treatment

- Data centers and mission critical facilities

- Process industry

- Research laboratories

- Electronics and electrical industry

- Information technology industry

- Food processing industry

- Rail and metro facilities

- Fertiliser industry