Approximately 94% of the electrical energy used by an Industrial Air Compressor is converted into heat and loss through radiation in the compression process. The remaining 6% is converted into compressed air heat losses.

There is huge potential to harness the waste energy and convert them to more meaningful use for making a greener earth. Energy saved is energy created and adds to the bottom line. We can tap the waste energy from screw compressors by the use of heat recovery systems.

A properly designed heat recovery unit can recover anywhere from 60- 94 % of the available thermal energy (as low grade heat) to generate warm water. This warm water can be used as a driving energy source for Adsorption Chillers (Silica Gel + Water pair).

How Bry-Air Adsorption Chillers Can Help?

The Adsorption Chiller can produce chilled water at 7°C that can be used for air conditioning or process cooling as the case may be. This will save huge Electrical Energy being used for cooling applications and help in reducing the CO2 emissions. Additionally, it ads up to cost-efficiency and reducing the running cost of the plant. The payback period will vary from 2.5 years to 4 years depending on the hours of usage and size of the compressor.

Greener Earth + Savings

Tentative Cooling Potential from Oil Injected Screw Air Compressors

|

|

Nominal Compressor

kW ( Oil Injected Screw Compressor)

|

Recoverable

Energy (kW) |

Cooling

Potential (TR) |

|

75

|

68 |

8.0

|

|

90

|

81 |

10.0

|

|

110

|

99 |

12.0

|

|

180

|

162 |

23.0

|

|

200

|

180 |

25.0

|

| 315 |

284 |

40.0

|

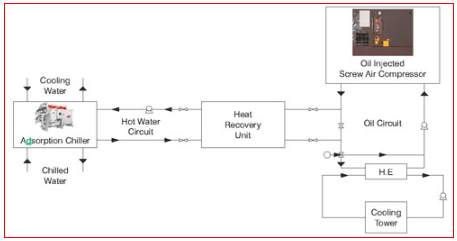

Typical Schematic on Waste Heat Energy Recovery for Adsorption Chiller from Screw Air Compressors

Bry-Air-make Adsorption chillers use potable water as the refrigerant, yielding zero ozone depletion and next to no global warming potential, by using low grade hot water from waste heat from flue gas as heat input to provide cooling instead of using electricity. Adsorption unit operates under vacuum with negligible moving parts, quiet and low noise. Adsorption technology is truly green, environment-friendly and sustainable.

Salient Features of our Adsorption Chiller Technology

- Environment friendly Chilling System

- Potable Water as Refrigerant

- Vibration Free and Noiseless Operation

- Negligible Technology

- Power Saving Technology

- No need to replace adsorbent (Silica Gel)

- No crystallization, corrosion, hazardous leaks, or chemical disposal issues

- Operating life of minimum 25 years